Description

How does it work

It develops a rise of pressure at a constant volume exceeding 15 MPa, more than enough to break up any material to destroyed. The tensile strength for most rock is less than 10 MPa. Reinforced concrete breaks at 3 to 5 MPa.

Application

Best results are obtained when using a hole with diameter up to 40 mm. Do not drill a wider hole.

To locate the holes, the following equation must be use as a guide :

S = D * K

in which :

S : practical hole spacing

D : borehole diameter in mm

Κ : cracking coefficient of material

Use the following table as a guide.

| Type of material to be broken | Κ | Free standing blocks | Block enclosed or with little clearance | |||

| Distance between holes (cm) | Consumption

(Kg/m3) |

Distance between holes (cm) |

Consumption (Kg/m3) |

|||

| Rock | Soft | 15-11 | 60 | 4 | 44 | 10 |

| Hard | 12-9 | 48 | 6 | 36 | 15 | |

| Concrete | Non reinforced | 15-11 | 60 | 4 | 44 | 10 |

| Reinforced | 9-7 | 36 | 10 | 28 | 15 | |

| Highly reinforced | 7-5 | 28 | 15 | 20 | Τουλάχιστον

20 – 25 |

|

This table should be modified to take into account the formation of the rocks and their homogeneity

NOTES

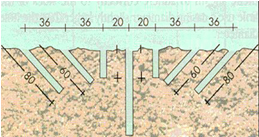

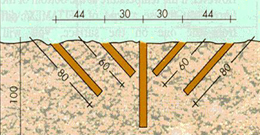

- Holes should first be drilled next to the edge, then the same distance must be kept from edge to the first row and between each following rows.

- In case there is no free face available it is necessary to make additional holes whose purpose is to encourage the formation of cracks. These holes are placed between the loaded holes where you want the first clearance surface to appear :

- When you want to guide the fissures in a particular direction the drill holes must be drilled closer together. Not all of these holes are loaded :

- Add 1-3% more than required water to slow down or reduce the effect of EXPANDEX in very hot conditions.

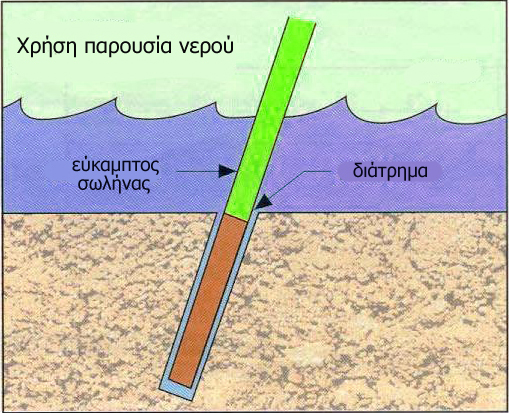

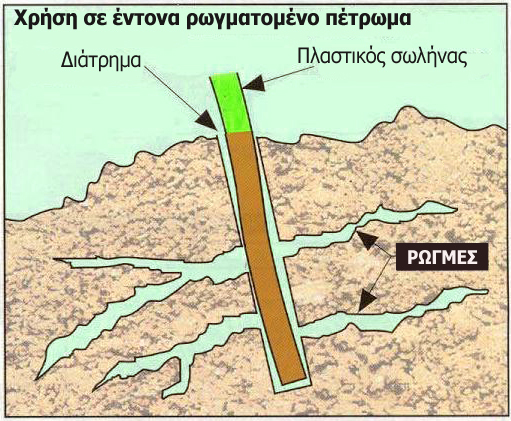

- When the materials to be broken is submerged in water, place into the hole a thin polythene sheath whose diameter is slightly larger than the hole diameter. Thentheholeisgraduallyfilledwith EXPANDEX.In this way, the water is held between the polythene sheath and the walls of the hole and is displaced from the hole. When using EXPANDEX under water (from 1 to 5 meters of water), it may be inserted by using a rigid PVC tube leading form the material and through the water to the outside.

General Instructions

- The effect of temperature

The choice of EXPANDEX type depends on the temperature of the block to be broken down. The temperature to be taken into account is the one measured on the surface and at the bottom of the hole. If these two temperatures correspond to the same powder type, the choice of product is easy.However, if the temperature at the bottom of the hole forces you to use a type different from the one on the surface, you will use EXPANDEX RED. In this case, the action of EXPANDEX will be slower but the risk of ejection iseliminated. - The effect of water

- A shortage of water in the mixture increases the temperature of the material leading to a violent acceleration of the exothermic reaction and, consequently, to a serious risk of ejection.

- If you use more water than the recommended the temperature of the material drops and it willslowdownorreducethe effect of EXPANDEX. If you use much more water than the correct quantity, the effect of EXPANDEX is neutralized.

- The effect of hole diameter

In a hole diameter wider than 40mm the evaporation of water increases rapidly accelerating the exothermic reaction leading to serious risk of ejection. This risk increases considerably as the diameter widens. - Mixing – way of loading

- Mix the paste until it becomes smooth. The paste must not have agglomerates in order to beeasy and safe to make the loading. Themixtureshouldbehomogeneousinthehole.

- The material must be put in place within 10 minutes after the mixing. Afterfewminutesthematerialstartstosolidifies and lose its homogeneity making the loading difficult.

- Absorbent materials

When breaking porous or absorbent materials, such as dry concrete, which are likely to absorb water from the EXPANDEX mixture it is advisable to either thoroughly dampen the material first with water and then fill the holes with EXPANDEX or to line the holes with a thin polythene sheath and to pour EXPANDEX into the polythene. To enable the polythene sheath to adhere correctly to the sides of the hole use a casing diameter slightly larger than the hole diameter.

- Consumption

The experience of using EXPANDEX shows that with aplasticbucketof 10 kgofEXPANDEXyoucanloadabout 10 meters of a hole with diameter 35-38mm.

Applications

Α. Concrete

-

- Enclosed

a. Semireinforced b. Lightly or non reinforced

Open a V or X cut. Then use bench blasting techniques Create a decompression area Spacing between holes: 20cm from the cut Spacing between holes: 30cm from the cut - Open faces

a. Semireinforced b. Lightly or non reinforced

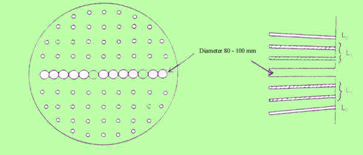

Drill not more than 40 mm diameter holes on 80% to 90% of the block. Pattern: 25-30cm Pattern: 30cm Pattern: 30cm Pattern: 30cm

- Enclosed

B. ROCK

-

- Enclosed

a. Hard: basalt, granite, sandstone, hard limestone

b. Soft: soft limestone, slate marl

Create a decompression area. Give maximum angle next to the cut when reaching edges use almost vertical holes Spacing between holes: 20cm from the cut Spacing between holes: 25 to 30cm from the cut - Open faces

a. Hard: basalt, granite, sandstone, hard limestone b. Soft: soft limestone, slate marl

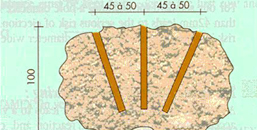

Drill not more than 40 mm diameter holes on 80% to 90% of the block Pattern: 30cm Pattern: 45-50cm

depending on the lie of the rock bed

- Enclosed

C. SPECIAL APPLICATIONS

-

- Breaking semi-enclosed rock by drilling not more than 40 mm diameter holes

Rock Pattern Inclination Soft 40-60 20-30ο Medium 35-50 Hard 30> - Breaking rock in cylindrical shape by drilling not more than 40mm diameter holes

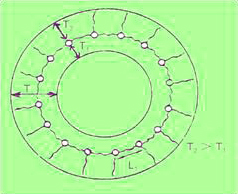

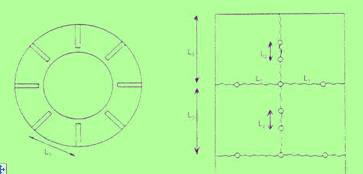

Rock Pattern (L1) Pattern (L2) Soft 35-45 30> Medium 30-40 25> Hard 30> 30> - Breakingconcrete in cylindricalshape

- Α. By drilling not more than 40 mm diameter vertical holes

Pattern (Τ) 20-100 cm Pattern(L1) 60-150 cm (L2) 15-20 cm (L3) 10-20 cm For reinforced concrete reduce the patterns about 40-60%

- Β. By drilling not more than 40 mm diameter horizontal holes

Pattern (L1)

40 cm

(L2)

15-20 cm

(L3)

10-20 cm

Inclination:

10-15ο

For reinforced concrete reduce the patterns about 40-60%

- Α. By drilling not more than 40 mm diameter vertical holes

- Breaking concrete walls and foundations by drilling not more than 40mm diameter holes

Patterns in non reinforced concrete 40-50 cm Patterns in light reinforced concrete 35-40 cm Patterns in reinforced concrete 20-25 cm

- Breaking semi-enclosed rock by drilling not more than 40 mm diameter holes

Packaging

EXPANDEX is available in a plastic bucket that contains a polythene bag which holds 10 kg of the cracking agent.

Depending on the temperature of the material to be destroyed, two different types of EXPANDEX are used:

- BLUE :Forcoldmaterials (5-20°C). Reaction time is around 5 to 15 hours,

- RED :Forwarmmaterials (20-35°C). Reaction time is around 2 to 8 hours.

PREPARATION OF EXPANDEX

- Fill the bucket with CLEAN and COLD water. On the inside of the bucket, there is a precise mark to indicate the quantity of water required for the mixture (2,7 lit for red buckets and 2,3 lit for blue buckets).

- Pour in all the powder, mixing all the time.

- Mix the paste until it becomes smooth. For safety reasons use a mechanical stirrer. This will ensure the mixture is homogeneous

- Fill the holes right up to the top.

NOTES

- The exact proportion of water and powder is very important for the success of the application.

- The use of stemming is not necessary.

- It is recommended not to filltheholesrightuptothetopif the temperature is above 30°C.

ATTENTION

- The mortar must be put in place within ten minutes after mixing.

- Do not stand over the filled holes.

Contact Us

For more information and assistance please do not hesitate to contact with the sales and technical department of EXTRACO SA.

90, 3rd SEPTEMVRIOU STREET

104 34 ATHENS

Tel : 210 8251248 -9

Fax : 210 8847360

Email : [email protected]