Description

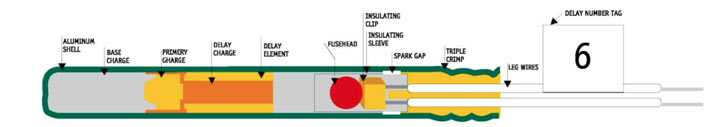

Electric detonator consists of an aluminum shell, which contains the explosive charge, the delay element and the fuse head. The required electrical energy for the initiation of the detonator, is supplied by two plastic-insulated metal wires called “leg wires”.

The explosive charge consists of a base and a primary charge. The delay element contains a pyrotechnical chemical substance that burns with a predetermined speed. By using pyrotechnical substances with different burning speeds, detonators with different delay times are obtained.

The fuse head consists of two metal contact foils, connected on one side by a bridge wire. The other two ends are attached to the Leg wires. When sufficient current is passed through the bridge wire, the latter is heated up and ignites the fuse head. The resultant flame initiates the delay element and the explosive charge. Leg wires are solid conductors of either tinned copper or steel, covered with plastic insulation. The free ends of leg wires are shunted for protection against stray currents. The delay period number of each electric detonator is marked on a tag attached to the leg wire.

Application

Electric detonators offer a great degree of safety during explosive’s initiation. It is possible to check all connections with suitable instruments, thus reducing the risk of misfires. Moreover, firing in a round can be controlled from a protective area.

Depending on the fuse head sensitivity, electric detonators are classified as normal sensitive I (type A), medium insensitive II (type F) and highly insensitive IV (type P). Medium insensitive electric detonators provide a high level of protection against stray currents or unintentional initiation. The firing impulse required for the assured firing of a series of type “F” detonators is much higher than for “A” detonators. Type “P” detonators are mainly used in site conditions where static electricity, stray currents, high-voltage and power transmission Lines are present. Highly insensitive detonators are supplied only with tinned copper leg wires in order to reduce the circuit resistance and the amount of energy required for initiation.

Electric detonators are manufactured in series with a predetermined time delay between successive delay intervals (periods). They are distinguished as half-second and millisecond delay electric detonators. Half-second electric detonators have a 500 ms delay between successive delay intervals. They are mainly intended for underground blasting operations where enough time is required to make room for the movement of the blasted rock.

Millisecond electric detonators are produced with a 25, 30 and 50ms delay between successive periods. The slight difference between successive delay intervals has a great impact in the blast progress. Previously detonated drill holes affect the structure and the strength of the rock, thus supporting the work of subsequent holes. This course of detonation provides better rock fragmentation, significantly less vibration and better control of the blast (fly rocks, etc.). Moreover, it is possible to increase the spacing between drill holes and reduce drilling and explosives volume. Millisecond electric detonators are best suited for surface and trench blasting operations.

WARNING!

It is not allowed to use electric detonators from different suppliers or fuse head sensitivity in the same round.

Storage

Electric detonators should be handled and stored separately from explosives according to the national laws and regulations. Storage premises should be kept clean, dry and well ventilated. Provided that storage conditions are appropriate, it is recommended to use electric detonators within 24 months. Product shelf life expansion can be verified after examined by the supplier.

| Group I – Sensitive Electric Detonators | |||

| Instant | Millisecond | Millisecond Permissible | |

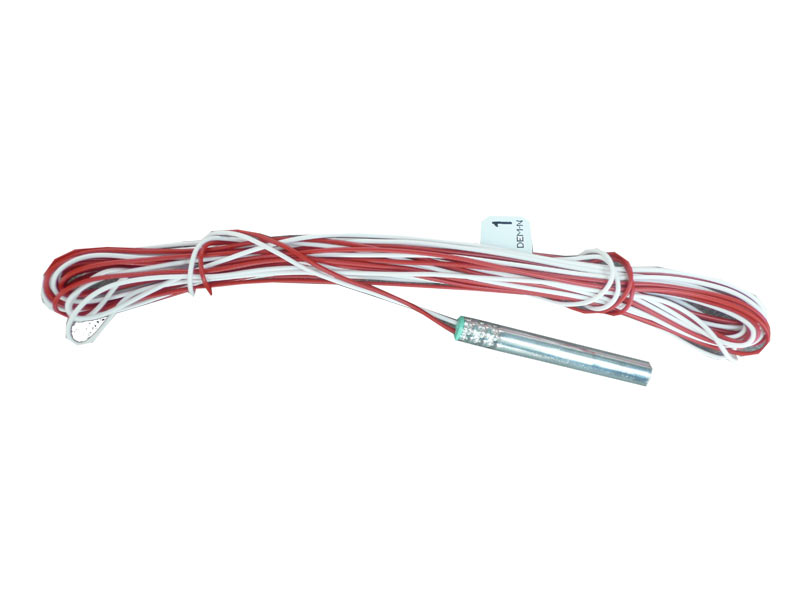

| Product name | 0-Ν | DEM-N | DEM-N |

| Delay numbers | 0 | 1-20 | 21-30 |

| Delay Interval | 25 ms | 50 ms | |

| Shell Material | Aluminium | Aluminium | Aluminium |

| Leg Wire Material | Steel or Copper | Steel or Copper | Steel or Copper |

| Insulation color* | white/red | white/red | white/white |

| Group II – Insensitive Electric Detonators | ||||

| Instant | Millisecond | Millisecond Permissible | Half- Second | |

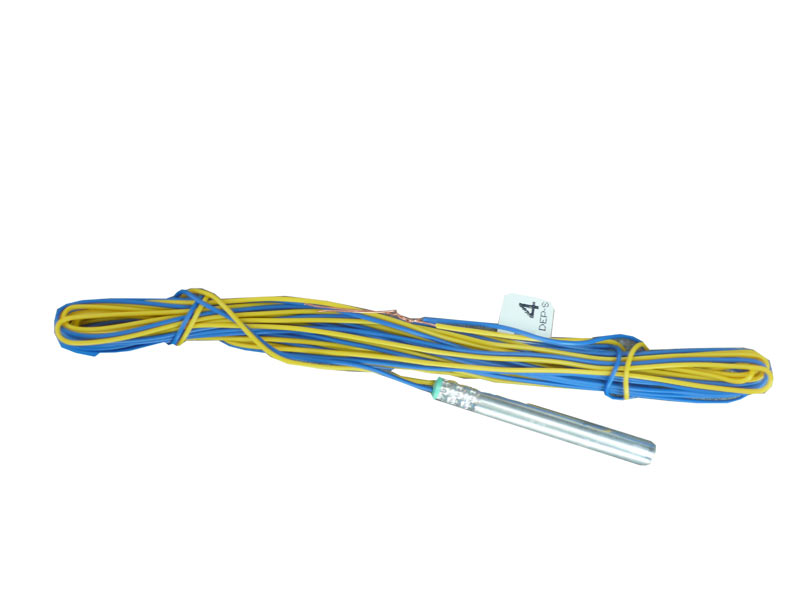

| Product name | 0-S | DEM-S | DEM-S | DEP-S |

| Delay numbers | 0 | 1-30 | 1-16 | 1-12 |

| Delay Interval | 25&50ms | 30ms | 500ms | |

| Shell Material | Aluminium | Aluminium | Copper | Aluminium |

| Leg Wire Material | Steel or Copper | Steel or Copper | Steel or Copper | Steel or Copper |

| Insulation color* | yellow/red | yellow/red | yellow/yellow | yellow/blue |

| Leg wire characteristics | ||||

| Wire Diameter (mm) | S.W.G. |

Resistance (ohms/100m) Copper Steel |

||

| 0.5 | 25 | 8.9 | – | |

| 0.6 | 23 | 6.1 | 42.0 | |

| 0.7 | 22 | 4.5 | 30.9 | |

| 0.8 | 21 | 3.4 | 23.7 | |

| Group IV – High Energy Electric Detonators | |||

| Instant | Millisecond | Half- Second | |

| Delay numbers | 0 | 1-30 | 1-12 |

| Delay Interval | 25&50 ms | 500ms | |

| Shell Material | Aluminium | Aluminium | Aluminium |

| Leg Wire Material | Copper | Copper | Copper |

| Insulation color* | brown/red | brown/red | brown/blue |

Classification

Commercial Name: 0-S, DEP-S, DEM-S, 0-N, DEM-N

Technical Name: Electric detonators

UN-number: 0255

Division/Compatibility Group: 1.4B